Choose the best

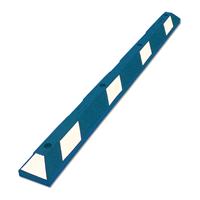

parking wheel stops on the market. Resistant to extreme temperatures, ultraviolet light and precipitation, including ice, road salt and oils.

-

• Wheel stops are made from 100% Recycled Rubber car and truck tires. We stay eco-friendly, you keep your parking lot safe.

- • Blue wheel stops are also available to help clearly mark handicap parking.

- • Rubber stops save you money! Studies have shown that over a 10-year period, concrete wheel stops could cost six times more than recycled rubber models due to cracking/maintenance issues.

- • Rubber conforms to uneven surfaces and doesn't fade in the sun like plastic wheel stops.

- • For more information, visit our - Rubber Parking Stops FAQs

Rubber Wheel Stop, 6 ft. : TireBoss Parking Wheel Stop -... Part #:K2-1018 4" x 72" Rubber Wheel Stop - Parking Bumper Verified PurchaseMakes it easier to park our new in the garage.

Heavy but works well.